Quality Assurance for Automotive Components

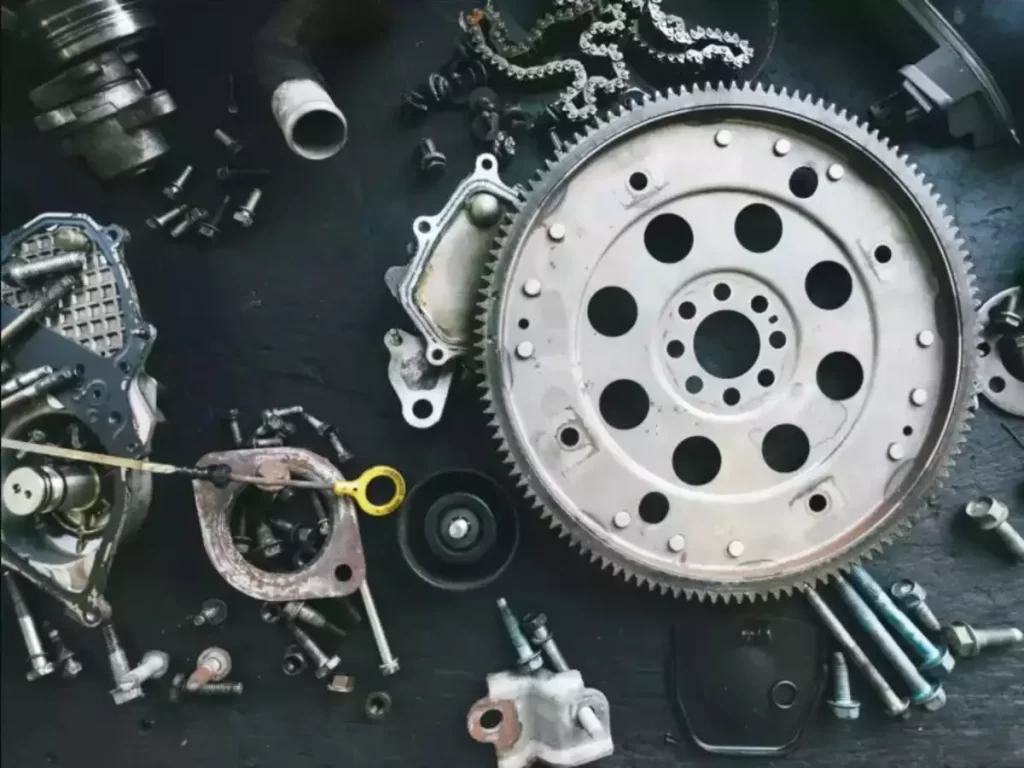

Automotive components are the parts of a vehicle that determine its performance and potential. An automobile engine is one of the most important parts, and many components are used to improve its performance. These components are typically made of metal, plastic, and rubber. In addition to mechanical components, automotive vehicles contain electrical systems and electronics. To help keep these parts running smoothly, they must be built to a high standard.

Some manufacturers use airflow and PLC testing to ensure quality. While these methods can provide information about the quality of components, they often miss defects that will cause problems later. Using Sciemetric technology during manufacturing can help detect defects before they become problems. This technology allows manufacturers to test all critical manufacturing processes to ensure the quality of the components.

The automotive components industry is an important contributor to the UK economy and is vital to vehicle production worldwide. The Automotive Components Section of SMMT provides effective representation for the industry. Its committee includes top multi-national companies as well as SMEs. The committee meets quarterly and provides input to the SMMT on the future direction of the industry. Membership of this committee is open to all companies involved in the manufacturing of automotive components in the UK.

Advanced technologies have made automotive components increasingly complex. Some examples include power/drive systems, fuel systems, exhaust/cooling systems, sensors, connectors, and controls. Automotive components also utilize coating for adhesion and film-forming. These processes are necessary to prevent frictional failures and protect the components’ surfaces. These coating processes are particularly critical when small spaces are involved.

Lightweight components require innovative material concepts and processes to produce them. For example, in the future, electromobility is expected to take a major role in vehicle manufacturing. For example, forming processes can improve the performance of electrically powered parts. The battery housing, a critical component in crash safety, needs to be protected.

Another automotive component that must be carefully designed to optimize its performance is the brake. This is a safety-critical system that must meet stringent environmental and cost demands. The feel of the brake pedal is one of the first points of contact between the driver and a vehicle. In addition to performance, brake pedal feel can contribute to a vehicle’s quality perception.

Automobile components also undergo rigorous tests to ensure they are made of high quality and meet industry standards. SATRA assists manufacturers and suppliers with testing by providing independent assurance testing services. This includes tests against international and national standards and OEM testing specifications. SATRA also has its own chemical analysis laboratory to ensure that automotive components are as safe as possible.